Engineering an Energy Efficient,

Adaptable Hybrid Bicycle Motor System

(EEEAHBMS)

By

Scott

Denenberg

Submitted

to:

The Weller Foundation Inc.

The Barton L. Weller Scholarship

2002-2003

April 8, 2003

Engineering an Energy Efficient,

Adaptable Hybrid Bicycle Motor System

(EEEAHBMS)

By

Scott

Denenberg

Submitted

to:

The Weller Foundation Inc.

The Barton L. Weller Scholarship

2002-2003

April 8, 2003

Table of

Contents

0. Preface

1. Project Description

1.1 Combining Human and Electric Power

1.2

Energy Efficient Regenerative Braking

1.3 Adaptability

1.4 Safety

2. Goals for Learning

2.1 The Engineering Process

2.2

Power Electronics

2.3

CAD (Computer Assisted Drawing) design

2.4

Software design

2.5 Interactive C

2.6

Advanced Circuitry

2.7 Testing and Debugging

3. Brainstorming Designs

3.1 Drive System

3.1.1 System Design

3.1.2 Motors

3.1.3 Batteries

3.1.4 Drive Wheels

3.2 Control System

3.3 Regenerative Breaking System

3.4 Mounting System

3.5

Safety System

4. Collecting Hardware

4.1 Motor

4.2 Batteries

4.3 Sheave and Bushing

4.4 Channel

4.5 H-Bridge Controller

4.6 5K Potentiometer

4.7 HandyBoard (HB)

4.8 Battery Charger

4.9 Bicycle Tire and Tube

4.10 Miscellaneous

5. Construction

5.1 Saddlebag

5.2 T-hinge and Aluminum Angle Stock

5.3 Motor and Batteries

5.4 Mounting of Saddlebag

5.5 Rear Control Box

5.6 Front Control Box

5.7 Trimming the Channel

5.8 Rear Reflector

6. Electronics

6.1 Batteries, Controller and Motor Circuit

6.1.1 Rear Control Box Electronics

6.1.2

Front Control Box Electronics

6.2 Current Sensor Circuit

6.3 Odometer Sensor Circuit

6.4 Printed Circuit Board in Rear Electronics Box

7. Software Design and Implementation

7.1 Learning Interactive C

7.2 System Requirements

7.3 Software Requirements Document

7.4 Implementing Software

8. Testing, Debugging and Results

8.1 Initial Testing of Motor, Controller, and

Batteries

8.2 Testing of the Current Sensor

8.3 Testing of the Odometer

8.4 Software Debugging

8.5 Final Testing and Results

9. Support

9.1 Jeffrey Denenberg

9.2 Steven Buroff

9.3 Motors and Drives

9.4 The Trumbull Business Education Initiative

9.5 Larry Farrell

9.6 The Bass Family and The Gottlieb Family

9.7 Danielle Lenois

10. Next Steps

10.1 Complete Software

10.2 Stabilize Physical Structure

10.3 Battery Tray

10.4 Lower Resistance Current Sensor

10.5 Further Testing of EEEAHBMS

10.6 Belt Friction Drive

10.7 Lighten Entire Structure

Appendices

A. Costs of EEEAHBMS

B. Electronics Connections

C. Software Requirements Document

D. EEEAHBMS Software

0. Preface

This report documents the Engineering an Energy-Efficient, Adaptable Hybrid Bicycle Motor System project from conception to completion. The report follows a structure that mimics the engineering process which guided the project, beginning with a general project description and goals for learning (Sections 1 and 2). The report documents the design process (Section 3), describes the process through which the hardware was purchased (Section 4), details how the physical structure of the motor system was built (Section 5), explains the electronics and circuitry of the bicycle (Section 6), and documents the software component of the project (Section 7). Finally, the report concludes with the testing, debugging, and results of the project (Section 8), a record of all of the support given towards completing this project (Section 9) and future intentions for the project (Section 10).

Special thanks are due to Jeffrey Denenberg, Steven Buroff, the Trumbull Business Education Initiative, and Motors and Drives, for large donations of time and materials.

1. Project Description

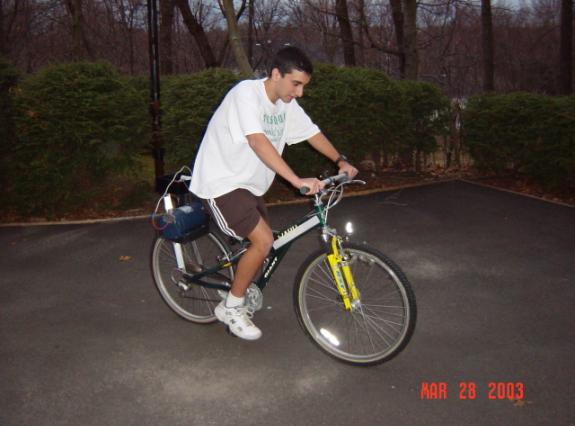

The idea for Engineering an Energy-Efficient, Adaptable Hybrid Bicycle Motor System (EEEAHBMS) stems from the recent burst in popularity of hybrid cars that utilize the combination of a combustion engine and battery power for optimum efficiency. The goal of this project is to create a similar union between human power and electric power, turning a bike into an efficient and practical machine for long distance travel.

1.1 Combining Human and Electric Power

A bicycle is often an unreasonable form of long distance travel because pedaling is exhausting, especially when pedaling uphill. A hybrid system overcomes this difficulty. The rider will select a desired speed at which he wishes to travel. The bicycle will have an onboard computer making constant comparisons between the current speed at which the bicycle is traveling and the inputted target speed of the rider. Based on this data, the computer will execute one of two general scenarios:

1. When peddling or traveling faster than the desired speed, the motor will act as a generator and send the extra energy provided by the rider into the battery for later use, slowing the bicycle down more efficiently than brakes (see section 1.2 Energy Efficient Regenerative Braking).

2. When traveling at less than the desired speed, the motor will provide the extra power required to achieve the desired speed.

The result will be a machine that effectively combines the power of man and electricity and makes it practical to use the bicycle for longer distances.

1.2 Energy

Efficient Regenerative Braking

The largest inefficiency in riding a bicycle is in the braking system. The essence of

braking is the removal of the kinetic energy of motion from the bicycle. When hand brakes are utilized, brake pads clamp down on the wheel, slowing down its rotation. This means that the kinetic energy is being removed through friction. While this is effective, the energy lost due to friction will never be returned to the bicycle. It has been dissipated in the form of heat and sound.

This project aims to overcome this inefficiency. Rather than braking through friction when

the bicycle is traveling faster than the target speed, the regenerative braking

system will take the extra kinetic energy and channel it back into a battery

for future use by the motor.

1.3 Adaptability

The aim of EEEAHBMS is not to simply transform one bicycle into a hybrid between human power and electric power. Its aim is to create an efficient motor system that is universal for almost every bicycle. This universality revolves around the mounting arrangement. With very few adjustments, the EEEAHBMS mounting arrangement will be compatible with almost every bicycle, making it relatively simple to transfer from bicycle to bicycle. This project does not include the bicycle itself; EEEAHBMS is an independent system that can be removed and added to an arbitrary bicycle without affecting its functionality.

1.4 Safety

Safety is an important consideration for all newly designed systems. EEEAHBMS needs to be proven to be safe for use through many repetitive and deliberate tests, as well as incorporating many safety functions to address unexpected malfunctions during operation.

The EEEAHBMS is no exception. In addition to redundant testing throughout the course of construction, it will have multiple safety features just in case something goes wrong during use. Such safety precautions include:

·

an on-off switch

·

an emergency software and hardware shutdown switch

·

a current overload shutdown procedure

·

a routine that does not allow the motor to start until

the bicycle is traveling at a minimum speed of 3mph.

2. Learning Goals

Engineering an Energy-Efficient, Adaptable Hybrid Bicycle Motor System is a research and development engineering project that is heavily focused on research. While it is the development phase that creates the final product, the research and subsequent knowledge gained is prerequisite for the development.

2.1 The Engineering Process

As stated above, EEEAHBMS is an engineering project: an idea is being developed, designed, implemented and tested. Therefore, while there are many different components to this project, every single one of them is a branch of the engineering process. At the end, each of these different sections of the project represents research, learning and development along the way to the final product. Hence, the experience gained during the multi-step process will be relevant in real world engineering projects.

2.2 Power Electronics

The design of this

hybrid motor system hinges on an in-depth knowledge of power electronics. The entire project revolves around

understanding energy efficiency, energy exchange and energy storage. The main task of power electronics is

to control and convert electrical power from one form to another. The

topic of power electronics includes:

With efficiency a

large goal in this project, it is necessary that the relative energy

efficiencies of different motors, batteries and controllers are understood

before a selection and purchase of materials is made.

2.3

CAD Design

The construction of the physical structure and mounting

system of the motor system requires multiple custom-made metal components. Before a machinist can create these custom

made parts, an accurate and to-scale drawing needs to be created. The Computer Aided Design (CAD) software

CADKey ’97 R2 will be used. However, no

CAD program is intuitive and self-explanatory.

They all require some expertise in order to create a 3-D drawing that

makes physical sense. In order to gain

some fluency in the program, the included guided tutorials will be

followed. However, this in itself is

not sufficient. In addition, self

instruction through experimentation will be the main method of learning exactly

how CADKEY ‘97 R2 works.

2.4

Software Design

Software design is not a straightforward process. Approaching it with a rough outline and basic idea of what needs to be accomplished, much like an essay, is a mistake. Without an exact statement of how to implement the goals of the project, the software cannot be written. This is because each section of the software does not build on the last. Instead, the different portions of the program work together simultaneously. Therefore, just writing code from the beginning to the end like writing a book is not the correct approach.

With the guidance of a professional programmer, the correct procedure for software design will be learned and then followed. This includes listing the purposes and functions of the project, and then creating a detailed Software Requirements document before even beginning to program. During this portion of the project, the structure of the procedure-oriented programming language, Interactive C, will be learned in preparation for the program implementation.

2.5 Interactive C

One of the largest components of EEEAHBMS is its

software. Since the 68HC11 “Handy Board” Computer will be used as

the onboard computer to control the hardware, its programming language,

Interactive C, will also be used.

Interactive C is a subset of the C programming language, and mastery of

its use will be absolutely necessary if the software portion of this project is

to be completed.

Learning a

programming language is not a simple task.

In order to become familiar with the syntax of this programming

environment, some guidance will be necessary.

However, beyond this, self-guided experimentation and the creation of

test programs will provide the experience needed before diving into this large

programming project. The EEEAHBMS

programming in itself will be a learning process as mistakes will be

continually discovered during the frequent testing and debugging.

2.6

Advanced Circuitry

The electricity and

magnetism portion of a Physics C course provided the foundation for the

electrical knowledge needed to complete the circuitry component of

EEEAHBMS. However, the project requires

knowledge that goes beyond the scope of that course.

Additional knowledge

is required in the areas of:

·

Digital Logic

and Boolean Algebra

·

Operational

Amplifiers

·

Voltage

Dividers

·

Capacitors

Digital Logic and

Boolean Algebra are necessary to understand the 7493 4-bit binary counters

which will be implemented in the speed sensor circuit.

An operational

amplifier amplifies a voltage according to the ratio of resistors surrounding

it and will be used to amplify the small signal from the current sensor. Also necessary for the current sensor is a

voltage divider, which is essentially the exact opposite of an operational

amplifier. It creates a point in the

circuit where the voltage is reduced to a fraction of the original.

Finally, while

capacitors were covered in Physics C, their use for this project was not

covered. In EEEAHBMS, a capacitor will be used as a

filter for a pulse-width modulated square wave. The purpose of this filter will be to make the average value of

the current from the H-bridge readable.

All of these topics

will be discussed in more detail later in the report.

2.7

Testing and Debugging

The last, and often

most difficult part of the engineering process, is testing and debugging. Unfortunately, one of the rules of

engineering is that nothing works perfectly the first time. There is always some unexpected occurrence

that needs to be solved after the fact.

The goal of the testing portion of the process is to pinpoint the error;

debugging is the process of repairing the mistake.

In order to be a

successful tester and debugger, a technique needs to be developed. It’s not always as straightforward as a

problem and a solution. Often,

innovation and clever manipulation of the resources at hand are necessary. There is a direct relationship between the

complexity of a project and the amount of troubleshooting that needs to be

done. Due to the complexity of

EEEAHBMS, there is bound to be more than enough testing and debugging to be

done. This experience will provide an

accurate representation of working in the real world of engineering.

3. Brainstorming Designs

The first few weeks

of work on EEEAHBMS were spent researching the feasibility and functionality of

different physical designs. Each

possible design was evaluated for its strengths and weaknesses, and then a

final design was chosen. While no

construction was accomplished during this period, the necessary material list

was created and a general design was finalized. Without a brainstorming period, no project can be successful.

3.1

Drive System

Motorizing a bicycle

is not an original idea. While there

have been no efforts to create a human power - electrical power hybrid as

EEEAHBMS aims to accomplish, many different drive systems for motorized

bicycles exist. Therefore, looking

towards other system designs was a logical place to start.

3.1.1 System Design

The simplest,

cheapest and most widely used drive system is a friction drive. A

friction drive consists of a motor turning a wheel which turns the wheel of a

bicycle through friction. While it can

be effective if correctly implemented, it does have a number of drawbacks. All of the drawbacks seem to revolve around

“slippage”. Since the only method of

connection between the motor’s drive wheel and the bicycle wheel is friction,

the entire system is liable to slip.

And, with slippage, there is a loss of energy and efficiency, as well as

the potential for wearing down and ruining the wheel. In order to overcome slippage, the original wheel of a bicycle is

often scrapped, especially if it is a mountain bicycle. Mountain bikes have especially bumpy treads,

and this bumpiness limits the surface area between the drive wheel and the

bicycle wheel. Therefore, a rough

bicycle wheel, a compromise between a slippery smooth wheel and the mountain

bike wheel, is ideal. However, there is

yet another problem. If the wheel gets

wet, there is an increased danger of slipping.

While this is only a difficulty if it is raining, it needs to be taken

into consideration.

The next drive

system is actually a number of variations belt pulley which involves a motor driving a belt which drives

a pulley on the shaft of a bicycle. The

different variations include different types of belts:

1. Friction belts

2. Chains

3. Toothed belts

The tooth belt is

the compromise between the friction belt and the chain. Motorcycles are the classic example of a

“motorized bicycle” that use this model of a belt pulley. However, this design has its own drawbacks

as well. This design does not lend

itself well to the EEEAHBMS because it is not adaptable. The pulley stem that needs to be mounted to

the wheel complicates the mounting arrangement and relies too heavily on the

structure of the hub of the bicycle wheel.

In addition, the belt pulley is dangerous. An exposed drive belt is a threat to the rider, because if a

shoelace or a piece of clothing gets caught, it will be drawn into the

motor. This makes it necessary to build

a shield around the belt system, creating even more complications and making

the system bulkier and heavier.

A third drive system

is the hub design. This design consists of a motor built into

the hub of the bicycle. While it is the

ideal drive system it terms of power and mounting economy, it has many draw

backs that far outweigh its advantages:

1. A hub motor is extremely expensive, and in order to get enough power

to accomplish the goals of EEEAHBMS, the budget would be exhausted on the motor

alone.

2. A hub motor is also extremely specialized, and the electronics

required are beyond the scope of this project.

The reasons for this will be discussed later.

3. Because the hub motor would be built into the hub of the bicycle, it

makes adaptability difficult.

4. A hub motor does not do regenerative braking. Instead of acting like a generator when it

needs to slow down, the hub motor free-wheels, or coasts to a stop.

For these reasons,

the hub drive design did not lend itself well to EEEAHBMS.

The final drive

system design is an original one devised while researching all of the different

possible drive systems. Its design is a

variation on the belt pulley drive. It

has been named the belt friction drive. It consists of a motor driving a belt which

is attached to a free wheeling pulley on the other side of the wheel. This belt is pressed down onto the wheel and

it drives the wheel through friction.

It has many advantages over the other drive systems. While the belt friction drive is similar to

the friction drive system because it moves the wheel through friction, it does

so over a much larger surface area than the friction drive wheel would. Therefore, slippage is much less of a

problem. Belt friction drives are also

portable from bike to bike because the belt friction drive does not involve

mounting directly onto the wheel of the bicycle.

After analyzing the

different options for the drive system, the top choice was the original design

of the belt friction drive. Beyond

being one of the simplest, most effective, and containing the least drawbacks,

it also added originality to the bicycle design that can be patented in the

future.

However, when

choosing a design, the top choice is not always the right choice. When attempting to make a concrete drawing

of what the design would look like, it became obvious that the belt friction

drive was overly complicated for a first attempt. Since any overly complicated design is bound to fail, the

friction drive was chosen. The

drawbacks of the friction drive system are easily overcome, and it is by far

the easiest to implement. In addition,

the friction drive is the first step towards the belt friction drive. Once the friction drive is functioning, with

the addition of a belt and a free wheeling pulley, it can be adapted into a

belt friction drive. Therefore, the design choice was to build a friction drive

system with the intentions of adapting it to a belt friction drive system in

the future.

Based on this system

design, it is possible to move onto more specific questions regarding the drive

system:

1.

What type of

motor will drive the bike?

2.

What type of

battery will supply the power to the motor?

3.

What type of

wheel will be used as a drive wheel?

To decide on a type

of motor, battery and drive wheel, the same process of enumerating all of the

different possibilities and then listing their strengths and weaknesses was

followed.

3.1.2 Motors

The first class of

motors was the very low cost motor. Every motor has a field and coils that move

with respect to each other. In general, the coils rotate on an armature through

the field, using brushes to continually flip the current in the coils. The flipping of currents allows the coils to

have the correct magnetic polarity to be attracted and repelled by the field at

the appropriate times, keeping the motor running rotating. There are exceptions to that rule

however. In some motors, it is the

field that rotates and the coils that remain stationary. In these low cost motors, the field is

created by a separate field winding.

While this creates a very light motor, the very low cost motors are not

terribly efficient. Much energy is wasted

in the current that flows through the field windings. While controlling the field current provides a very easy way to

control the speed of the motor, it also poses a problem. The current in the motor and the speed of

the motor are an inverse relationship.

The lower the current, the faster the motor rotates and vice versa. However, if the current in the field

windings reaches zero, or even approaches zero, the motor will spin too quickly

and destroy itself.

Another class of

motors is the brushless motor. An example of a brushless motor is a hub

motor. They are extremely efficient,

very powerful, and lightweight.

However, they require very complicated electronics because, instead of a

brush, electronics inside of the motor flip the currents of the field windings

and the rotating coils to keep the motor turning. While this is an extremely effective approach, it would be

necessary to purchase all of the motor control electronics which would

shortchange the learning goal of EEEAHBMS. Therefore, the brushless motors were

not chosen.

The last motor class

is the permanent magnet motor. These motors sport a permanent magnet that

sets up a constant field as opposed to the field windings with the variable

field in the low-cost motors. While

this permanent magnet does cause the motor to be a little heavier, it also is

much more efficient. Also, the constant

field sets up a steady state speed. The

voltage put across the motor determines the speed that it will rotate at,

regardless of the load. Therefore, with

this type of motor, the speed would be independent of whether the bicycle was

going uphill or downhill. And, to make

things even simpler, the voltage has a direct linear relationship with the

speed of the motor. This makes the

electronics connected to the motor very simple. (See 3.2 Control System for more details on the electronics of

the bicycle.)

The information that

served as the first indicator of the linear relationship between voltage and

speed came from the following graph (found at

store.evparts.com/shopping/products/mt5113/Torque%20Curves.htm):

Figure 3a: LEM-130 Torque Curves

This graph shows

that the rotations per minute at the equilibrium speed (speed that the motor

accelerates to and then stabilizes) of a permanent magnet motor is independent

of the load placed on the motor. This

was intriguing, and, after further research, the fact that a permanent magnet

motor has a steady state speed was discovered (see 3.2 Control System for more

details).

Based on this

information, the motor class choice for EEEAHBMS was the permanent magnet

motor.

3.1.3 Batteries

The choices for

rechargeable batteries were:

1.

Nickel cadmium

and nickel metal-hydride

2.

Wet cell lead

acid

3.

Sealed lead

acid

Before the different

classes of batteries could be examined, a few calculations were required. By examining other motorized bicycle

designs, it was determined that to accomplish the goals of EEEAHBMS, a

half-horsepower motor was needed.

Taking into account some inefficiency, a half-horsepower is equal to

about 400 Watts, which is a measure of power.

And Power is equal to Voltage X Current. From some quick research on different gauge wire and the relative

currents they could handle, a 24 Volt battery (a convenient multiple of the

standard 12 Volt car battery) was chosen because that left the current that

needed to be handled at 20 Amps. And, a

reasonable 10 or 12 gauge wire can easily handle 20 Amps. Finally, the rating in amp-hours of the

battery was going to be determined by cost and weight, with a target amp-hour

rating of about 12. An amp-hour is a

measure of how much current a battery can supply before draining itself. (One amp supplied for one hour is an

amp-hour. And, 100 amps supplied for

1/100 of an hour is also an amp-hour.)

From research on the success of other motorized bicycles, it seems that

12 amp-hours would give the bicycle a range of 10 miles. Obviously, a higher rating in amp-hours is

desirable, but as the rating of a battery rises, so do its cost and its

weight.

The first class of

rechargeable batteries that was examined included nickel cadmium batteries and nickel metal hydride batteries. Both of these types are deep discharge and can be charged many

times before losing effectiveness. In

addition they have one of the best energy storage to weight and volume

ratios. They are such good batteries

that they are even used in hybrid cars.

However, nickel cadmium and nickel metal hydride batteries have some

serious flaws. Nickel cadmium batteries

have “memory.” These batteries, if not

fully discharged before charging, “remember” the degree to which they were last

discharged. Then, during the next power

cycles, this memory will prevent the battery from ever discharging below the

point to which it was discharged last, despite the fact that the battery is

capable of being further discharged.

Since EEEAHBMS will not always fully discharge a battery before charging

it back up, this characteristic is highly undesirable. While the nickel metal hydride batteries do

not have the same memory characteristic, both the nickel cadmium and nickel

metal hydride batteries are extremely expensive. For example, a 6 Volt nickel metal hydride cell, rated at 1.2

amp-hours costs $20. If you connect 4

of these batteries in series, the desired 24 Volt rating is achieved. And if you connect 10 of these 4 battery

strings in parallel, a reasonable rating of 12 amp hours is achieved. Therefore, 40 batteries are required to

produce 12 amp-hours at 24 Volts. This

would cost $800, which is far above the budget for this project.

The second class of

batteries is the wet-cell lead acid

battery. These are the batteries that

are typically used in cars. While these

batteries store a lot of energy and are incredibly reliable, they do not like a

deep discharge. For example, on the

fourth or fifth time a car battery is drained completely from the headlights

being left on, it needs to be replaced.

Another drawback of the wet-cell lead acid batteries is that they need

to be maintained vertical at all times.

If tipped, these batteries are dangerous because of the acid they

contain. While a vertical orientation

can be insured inside a car under normal circumstances, a bicycle is much more

likely to be accidentally tipped.

The third class of

battery is the sealed lead acid battery. This battery is very similar to a wet-cell

lead acid battery; however its acid is captured in a gel or in a sponge-like

membrane. Therefore, tipping is no

longer an issue. In addition, the

sealed lead acid batteries can be discharged and charged over 500 times without

any harm to the battery, as long as a special battery charger is used and care

is taken not to overcharge or discharge the battery. And, finally, these batteries are not expensive. Two 12 V batteries, both rated at 12 amp-hours

cost less than $90, one tenth of what a nickel metal hydride battery would

cost.

Based on this

analysis, the battery choice for EEEAHBMS was the sealed lead acid battery.

3.1.4 Drive Wheels

The drive wheel is

the wheel that the motor drives, which in turn drives the bicycle wheel. This decision was fairly easy, as there were

only two possibilities with one having clear advantages.

The first

possibility was a grinding wheel. While this would provide a lot of friction

to the wheel, it had a serious flaw. If

the grinding wheel were to slip for any reason, it would do what it is made to

do: grind. And before long, the wheel

would be destroyed.

The other drive

wheel possibility was a sheave (pronounced

“shĩv”). A sheave is very similar to a pulley, with

the only difference being that a pulley is free wheeling and a sheave locks on

to a shaft. While a sheave does not

have as much friction as a grinding wheel, it is much more suited for

EEEAHBMS’s purposes. It is not as large

of a threat to grinding the wheel down, it has features which make it easy to

connect to the motor, and it is compatible with the intentions to test a belt

friction drive in the future.

Based on this

analysis, the drive wheel class choice for EEEAHBMS was the sheave.

3.2

Control System

Once all of the

components of the drive system were selected, all of the other components

quickly fell into place. Based on the

selection of a permanent magnet motor, the control system needed to be able to

produce a variable voltage in order to control the speed of the motor. As previously explained, there is a linear

relationship between the voltage placed across the motor, and the speed of the

motor. And, this is independent from

the load placed on the motor. This is

true because as the motor speeds up, it produces a back EMF. This back EMF is basically an anti-voltage,

which is linearly related to the speed of the motor. When the back EMF equals the variable voltage supplied by the

controller, the motor stops accelerating.

For a permanent

magnet motor, the standard variable voltage supply is an H-bridge. An H-bridge is comprised of two sets of two

switches, making the shape of an H.

These sets of switches, when turned on and off, alternately switch the

battery positively and negatively across the motor. These switches flip back and forth approximately 1000 times per

second, and set up an average voltage across the motor. The average voltage depends on the duty

cycle, which is determined by an inputted voltage (from the Handy Board

computer). For example, if the switches connect the battery across the motor

equally positively and negatively, then the average voltage will be 0 as they

will cancel. However, if the duty cycle

connects the battery across the motor for 75% of the time positively, and 25%

of the time negatively, then the average voltage is 50% of the positive nominal

voltage, which in the case of EEEAHBMS, is 12 volts.

3.3

Regenerative Braking System

The design of the

regenerative braking system for EEEAHBMS is very simple; it only required

choosing an H-bridge that did regenerative braking. The decision on whether to make the H-bridge or to buy it was an

easy one. An H-bridge is a complicated

piece of equipment, and to build it from scratch would be unpractical when they

are reasonably priced. H-bridges rated

at 20 amps continuous duty are priced from $100-$150, depending on features.

H-bridges have three

major features:

1. Bidirectionality

2. Dynamic Braking

3. Regenerative Braking

A bidirectional H-bridge is capable of

running a motor forwards and backwards.

While this adds minimally to the cost of the H-bridge, it was

undesirable for EEEAHBMS. A bicycle is

not meant to run backwards, and if a bidirectional H-bridge was used, the

bicycle could start moving backwards accidentally and potentially hurt the

rider or the bicycle. For example, if

the H-bridge’s duty cycle connected the battery across the motor positively

only 25% of the time, the motor would run backwards at half speed. This is the opposite scenario from when the

battery was connected across the battery 75% of the time.

Another feature that

an H-bridge can have is dynamic

braking. Dynamic braking is the

capability for the H-bridge to short out the motor and shunt all of the current

to ground. This causes the motor to

stop immediately. Dynamic braking adds

to the price of an H-bridge because it takes extra transistors for the H-bridge

to be able to handle the current involved in shorting out the motor. The dynamic braking feature wasn’t required

for the EEEAHBMS because it stops the motor too quickly. Dynamic braking would cause damage to the

wheel and loss of control of the bicycle.

However, having an H-bridge that did include dynamic braking was not as

undesirable as a bidirectional H-bridge.

This is because it is difficult to accidentally enable the dynamic

braking feature. It requires an extra

connection and extra wiring that can easily be omitted.

Regenerative

braking is the H-bridge feature

that is most pertinent to this section of the design. The regenerative braking function requires that the H-bridge can

handle the flow of current in both directions: from the battery to the motor

and from the motor to the battery. And,

because transistors usually only like to conduct current in one direction, the

addition of transistors for the regenerative braking function does increase the

H-bridge’s price.

3.4

Mounting System

Once the basic

design of EEEAHBMS was created, the next step was to figure out how to mount it

on a bicycle. However, this wasn’t as

simple as figuring out how to mount EEEAHBMS on the bicycle in the garage. In order to achieve the adaptability goal of

the project, the mounting arrangement needs to be simple and compatible with

all bicycle frames.

After an informative

trip to Cycle Fitness in Monroe, and

a long discussion with the manager of the bicycle shop, a basic mounting

arrangement was designed. There are two

aspects of a bike that are universal: the bicycle seat and the rear axel. Therefore, these two locations are the

logical place to mount the motor. In

fact, these are also the two easiest places for mounting. The seat post of the bicycle seat provides

an easy, sturdy place for clamping, and the rear axel has threaded mounting

holes. Every bicycle has these standard

threaded holes for mounting rear fenders or carriers for babies and school

books.

While this mounting

arrangement is simple and compatible to most bicycle frames, there are a few

exceptions. The first exception is the

racing bike. Racing bicycles have very

thin frames, designed to be light and aerodynamic. They cannot safely support

the addition of a 60 pound motor system.

Therefore, EEEAHBMS will not be compatible with racing bicycles. However, this is not a terrible loss, as it

is difficult to imagine a bicycle racer wishing for electric assistance.

The other exception

is any bicycle that has a set of shock absorbers on the rear wheel. Rear shocks cause the rear axel to move

relative to the bicycle seat. And, this

is not compatible with a mounting arrangement that clamps onto these two parts

of the bicycle.

One last mounting

detail needed to be addressed. Since a

friction drive is going to be used, the bicycle cannot have a mountain bike tire. Mountain bike tires are very bumpy and have

a lot of knobby irregularities which are meant to increase traction and

stability off-road. However, these

bumps would prevent the drive wheel from having contact with a consistently

smooth and regular wheel surface.

Therefore, for mountain bikes, the rear tire would have to be replaced

in order to be compatible with a friction drive.

Once the mounting

arrangement was decided, the manner by which the weight of the motor and

battery of EEEAHBMS were to be distributed needed to be determined. Maintaining a balance on the bicycle wasn’t

going to be easy with a 23 pound motor and two 9 pound batteries. However, there is a logical solution. The two 9 pound batteries can balance the 23

pound motor if they are placed on the opposite side of the bicycle. So, a “saddle-bag” design for mounting was

adopted. A metal channel is mounted to

the seat post of the bicycle and supported by an angle-iron mounted to the rear

axel. Across this channel are

saddlebags with a compartment on each side of the bicycle: one side for the

motor and the other side for the two batteries. With this general design decided, the feasibility of the weight

distribution of the motor and batteries was proven.

3.5

Safety System

The final system to

be defined was the safety system.

Safety is always of foremost importance in design.

When researching

other motorized bicycles, a common safety precaution emerged: the motor would

not start unless the bicycle was already going 2-3 miles per hour. This is to prevent the bicycle from running

off on its own, without the rider on it, or before the rider is in control of

the bicycle. It’s a logical precaution

and was incorporated into the design of EEEAHBMS.

Another safety

measure that was incorporated was a computer shut down if the current spikes

above a specified “high water mark.”

The electronics of the bicycle isn’t rated to handle currents above 20

amps continuously, and, therefore, it needs to be protected from damage caused

by the motor pulling too high of a current.

With the computer monitoring the current, it is a simple safety measure

to have the software shut everything down if the current spikes above the high

water mark.

In designing a

safety system, redundancy is the key.

Therefore, in addition to the software shutdown if the current exceeds

the high water mark, there will be a hardware shutdown as well. This will be accomplished with a simple

fuse. If the current gets too high, the

fuse will blow; the metal inside the fuse will melt, breaking a circuit.

Another aspect of

the safety system concerned braking.

Regenerative braking is not appropriate for sudden, emergency

stops. Dynamic braking was first

considered for this purpose. It seemed

to be the easiest way to ensure a rapid stop.

However, during testing, this was proven to be highly unsafe because it

stopped the motor too quickly. A sudden

stop could damage the motor and the wheel, as well as causing the rider to lose

control.

Therefore, a more

elegant and less brute force solution to the requirement for a sudden stop was

designed. The handbrake serves as an

emergency switch. Pumping it causes the

computer to reset the bicycle’s desired speed to zero, which slows the bicycle

down quickly. And, with the bicycle’s desired

speed at zero, the handbrakes can then be used in tandem as they would normally

be used, achieving a quick and safe stop.

As another safety

precaution, there is be a main software shutdown switch as well as a hardware

shutdown switch. And, finally, there is

a main on-off switch. Once again,

redundancy is the key. However, the

main on-off switch cannot be flipped while the motor is in use because it is

not rated at high currents.

4. Collecting Hardware

Once the overall

general design for EEEAHBMS was completed, the next step was to purchase all of

the major components of the project.

For details on the prices of each component, see Appendix A Costs of

EEEAHBMS.

4.1

Motor

Based on the

EEEAHBMS design, the motor requirement was a ½ horsepower permanent magnet

motor, rated at 24 V and 20 amps continuous duty. So, the motor search began.

After shopping around on multiple websites, it was determined that

motors are extremely expensive. While

surplus motors are available on e-bay for between $150-$200, it was impossible

to find a motor with the correct specifications. This left a price range of $300-$400, which was unacceptable for

the EEEAHBMS budget.

After contacting Motors and Drives, a family owned

company, the motor search began to look more promising. Casey O’Donnell, an engineering student at

Fairfield University and member of the Motors

and Drives team helped to find the best motor suited for EEEAHBMS. And, after pinpointing the desired motor,

Casey donated it.

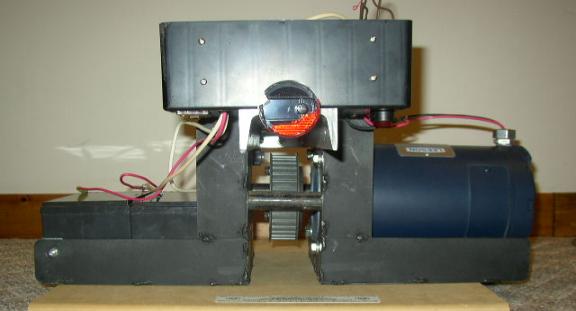

The motor chosen is

a Leeson #108051: ½ horsepower, 1800 rpm permanent magnet motor rated at 24V

and 20 amps continuous rating. This

motor was perfect for EEEAHBMS. And, if

it hadn’t been donated, the motor would have cost $365.00 plus shipping.

The Leeson motor

weighs 23 lbs. and has a 5/8 inch shaft with a hardened metal key. It is approximately 5 ½ inches in diameter,

9 ½ inches long and has a 2 inch long shaft.

The Leeson motor has four mounting holes on the face of the motor as

well as a base that is equipped for mounting.

Figure 4a: Leeson ½ horsepower motor

Later along in the

project an even better British LEM 130 motor was found for EEEAHBMS. However, while its specifications are

better, making it more powerful, much lighter and less bulky, it is more than

twice as expensive as the Leeson 1800, and it would have not been donated.

4.2

Batteries

The EEEAHBMS design

requires a 24 V sealed lead acid battery, rated at 12 amp-hours. After shopping around, it was determined

that there was no way to get batteries inexpensively. And, it was apparent that

the easiest way to achieve the voltage desired was to use two12 V batteries in

series. The most inexpensive batteries

at the desired ratings to be found were at www.Electricscooting.com. So, the two 12 Volt, 12 amp-hour batteries

were ordered for $95.90.

These sealed lead acid batteries weigh 9 lbs each, and are 5 15/16 inches long, 3 3/4 inches tall and 3 7/8 inches wide.

These batteries need a special charger because (see 4.8 Battery Charger) they do not survive overcharging, and they must be charged at a higher voltage than normal wet-cell lead acid batteries. When fully charged with the correct charger, the batteries are actually at 26 V.

Figure 4b: 12 Volt Sealed Lead Acid Batteries

The length of the life of these sealed lead acid batteries

is mainly dependent on how far they are discharged each time. The battery needs to reserve the bottom 20%

of its charge to prolong its life. Without this reserve, a completely drained

battery would give only 100 recharges. By using 80% of the battery capacity the

number of recharges increases to 400-500 cycles. If half of the available

charge is used during each cycle, the battery can survive 700-800 cycles.

Therefore, it is beneficial to avoid fully discharging the battery (information

found at www.currietech.com.au/products/uspd.htm#top).

4.3 Sheave and Bushing

The sheave (pronounced “shĩv”), identified in the EEEAHBMS design, is going to function as the drive wheel for the system. However, before shopping around for a sheave could begin, it was necessary to know the approximate target size for the sheave. This would determine the bicycle’s top speed. According to Connecticut state law, (found at ct.gov) a moped (motor-assisted bicycle) cannot have a top speed of over 30 mph. A moped with a top speed over 30 mph is considered a motorcycle, which requires a special license. Therefore, the top speed could not exceed 30 mph. To be safe, a top speed of 25 mph was selected.

With a top speed of 25 mph selected, and the motor’s top speed of 1800 rpm known, some calculations were made:

Since the circumference of the shiv = 14.67 inches = pD, the diameter of the sheave = 4.6 inches.

Once again, Casey O’Donnell of Motors and Drives came to the rescue. He found two industrial timing belt sheaves which would be perfect for EEEAHBMS’s purposes. One was a little less than 4 inches in diameter and the other was 4.3 inches in diameter. The 4.3 inch sheave was selected, as it would give the bicycle a maximum speed of 23 mph. Once again, Casey was more than generous, donating the sheave as well as the SDSX58 bushing that would adapt it to the 5/8 inch keyed shaft of the Leeson motor.

Figure 4c: Timing

Belt Sheave, Hardened Metal Key, and Bushing

On the left in Figure 4c is the industrial timing belt sheave, with the bushing on the right and the hardened metal key in the middle. The bushing and the hub are connected by 3 hexagonal-head screws that pull the bushing into a slightly tapered hole in the sheave. The taper creates a reliably balanced and secure connection between the bushing and the sheave. In fact, the tapered hole creates such a secure connection that it is nearly impossible to remove the bushing from the sheave once it is in place. In order to remove the bushing, you first remove the screws and then use those screws in three different holes. These holes are designed to do the opposite of the first three: they are meant to help the user push the bushing out of the sheave. With the extra force of the screw action combined with the lever arm of a ratchet wrench, it is possible to remove the bushing from the sheave.

The sheave and the bushing are made of hardened spring steel, making them very difficult to damage. And, because the sheave is a timing belt sheave, it has grooves for the belt it is meant to drive, making it perfect for the EEEAHBMS application. The grooves will provide nice friction between it and the bicycle wheel that it is driving.

The bushing and sheave mount onto the motor as follows: The hardened metal key is placed into the groove on the shaft of the motor and then the bushing slides over the key and the shaft. The key serves the purpose of creating an irregular, non circular shape for the bushing to connect with, so that the bushing cannot turn. Then a recess-hexagonal drive set screw is tightened down onto the metal key using an Allen wrench, securing the bushing onto the motor. Then, the sheave is connected to the bushing as previously described.

Figure 4d: Sheave and

Bushing Mounted on Motor

4.4 Channel

The metal channel, as described in the design portion of the project, serves as the “backbone” of the structure of EEEAHBMS. It is mounted to the pole supporting the bicycle seat and to the rear axel of the bicycle. And every other piece of the structure is mounted to it. Therefore, strength is an absolute requirement.

For about $10, two feet of standard industrial 3 inch channel was purchased from Magna Steel in Bridgeport, CT.

Figure 4e: Industrial

3 inch Metal Channel

This industrial channel is made of soft steel, which makes

it easy to drill holes for mounting.

And, even though it is very heavy, it is also very strong. The last 7 inches of the channel were

removed later in the project as they were unnecessary and their removal would

save weight. Details about this removal and the T-hinge mounted on the end of

the channel in Figure 4e can be found in section 5 Construction.

4.5 H-Bridge Controller

The EEEAHBMS design requires an H-bridge controller rated at 24V, 20 amps continuous duty. And, as described earlier, a desirable H-bridge would lack bidirectional control and have regenerative braking; dynamic braking was optional.

After a web search of H-bridge suppliers, it was apparent that a commercial unit would cost between $200-$250. After some more searching, an off-brand supplier who sold decent H-bridges for $150 was located. However, this was still above the EEEAHBMS budget. So, the search began for surplus H-bridges.

It turns out that an electric bicycle company that produced the EV Warrior bicycle went bankrupt recently. And, they had thousands of specialty Curtis 1505 commercial unit H-Bridge Controllers in stock when they went bankrupt. So, there are surplus Curtis 1505s on sale for $45 - $60. This was a steal. Curtis controllers are very high quality and would otherwise be priced at or over $150.

Figure 4f: Curtis

1505 H-Bridge Controller

The Curtis 1505 comes with its own mounting case and is unidirectional with regenerative and dynamic braking. The dynamic braking has two triggers. One trigger will enable dynamic braking if it is ever disconnected from the positive terminal of the battery, and the other trigger will enable dynamic braking if it is ever connected to the negative terminal of the battery. This was determined through trial and error experimentation, as limited documentation was available.

The Curtis 1505 also has a built in protection against

discharging the batteries completely. If the batteries ever drop below 18 V, then the controller

will shut down the system automatically.

Such a low voltage is a warning sign that the batteries are nearing

complete discharge.

Finally, the Curtis 1505 has

thermal protection. This consists of a

heat sensor that will shut down the controller if it exceeds a certain

temperature. This is to prevent the

controller from overheating due to high currents.

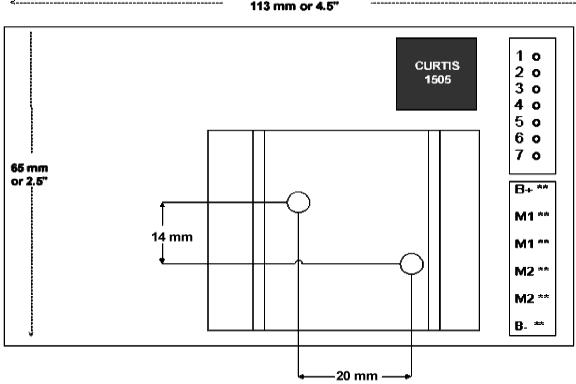

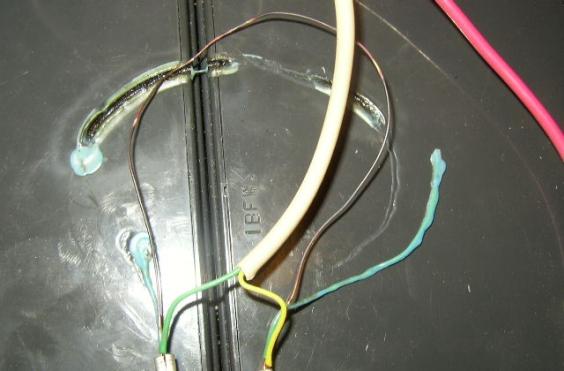

Figure 4g: H-Bridge Wiring

Figure 4h: H-Bridge Dimensions

Figure 4g is a wiring diagram of the Curtis 1505, and Figure 4h provides the physical dimensions of the Curtis controller. While Figure 4g also shows that the H-bridge has a built in current sensor, during initial testing, there was no evidence that the current sensor’s reading was accurate. So, it was not used and a different current sensor was devised (see section 6.2 Current Sensor Circuit for more detail).

The control for the Curtis 1505 is intended to be a 5k

potentiometer (see section 4.6 Potentiometer for more details). The 5k potentiometer outputs anywhere from

0V to 4V. If the output is zero volts,

the controller outputs 0V to the motor.

If the output is 4V, the controller outputs 24V. The relationship between the output of the

potentiometer and the output of the controller is linear. And since the relationship between the

output of the controller and the speed of the motor is linear, the relationship

between the output of the potentiometer and the speed of the motor is linear as

well. If any one of the three leads of

the potentiometer disconnects, the controller automatically switches to dynamic

braking.

4.6 5K Potentiometer

A potentiometer is basically a voltage divider. It has three wires connected to a resistor. The first wire is power, connected to one side of the resistor and having a certain given voltage. In the case of the 5k potentiometer, the resistor has a resistance of 5,000 ohms, and the power side of the resistor has a voltage of 4V. The second wire is connected to the other side of the resistor and is ground (0V). Therefore, the resistor has a voltage drop of 4V. The third wire is a wiper, connecting to anywhere between the other two wires, depending on where the knob of the potentiometer is turned. If it is turned all the way towards ground, then the third wire is at ground and carries a voltage of 0V. If it is turned all the way towards power, then it carries the full voltage. And, if the third wire is connected between the power wire and the ground wire, the third wire carries a fraction of the total voltage.

There are two main types of potentiometers: linear taper and logarithmatic taper. The names reflect the relationship between where the third wire is attached and what fraction of the voltage is carried by the third wire. In a linear taper, the relationship is linear. If the third wire is attached half way between, then it carries half of the total voltage. If it is logarithmatic taper, then the ratio is logarithmatic. For the purposes of EEEAHBMS, linear taper is ideal. Logarithmatic would be more complicated than necessary, and is more suited for uses such as audio intensity which are exponential in nature.

Therefore, the potentiometer used for EEEAHBMS is a 5k linear taper potentiometer. Its output is anywhere between 0V and 4V, and, as previously mentioned, the output is linearly related to the speed of the motor. The fact that the power wire of the potentiometer carries only 4V is very convenient. After the bicycle is working, the intention is to have the HandyBoard Computer control the speed of the bicycle, so that the HandyBoard can better protect against current surges. And, since the HandyBoard is capable of outputting up to 9V, having the HandyBoard mimic the potentiometer is trivial.

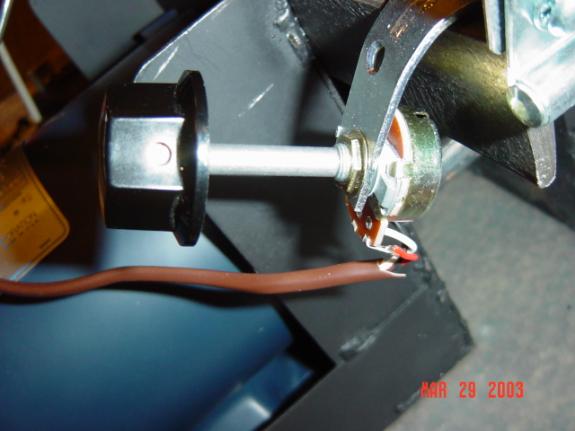

Figure 4i: 5k Linear

Taper Potentiometer and Knob

This 5k linear taper potentiometer was purchased at Radio

Shack for approximately $5.

Potentiometers are not expensive.

The knob on the end of the potentiometer was also purchased from Radio

Shack for approximately $2 and attached to the end of the potentiometer to make

the turning of the potentiometer easier.

4.7 HandyBoard (HB) Computer

The HandyBoard is a programmable robotics controller that was designed and built for MIT robotics students. Its programming language is Interactive C, an interpretive subset of ANSI C. Interpretive means that instead of compiling all of the commands into code prior to program execution, the program processes the commands as they come. While this makes Interactive C a little slower than ANSI C, it also makes it much easier to test and debug. But, since Interactive C is only a subset of ANSI C, some functions aren’t available. Even though Interactive C is somewhat limited and not truly a professional programming environment, it is perfectly capable of handling the software requirements of EEEAHBMS.

The HandyBoard and Interactive C provide a “persistent variable” feature. A value stored in a persistent variable will retain its value when the HandyBoard is reset, power cycled, or when the program initializer, main(), exits and is subsequently restarted. A persistent variable will be reset to the initial value when the program is downloaded into the HB. This function will allow the HandyBoard to keep track of information that spans multiple trips, such as distance traveled and energy flow.

Figure 4j:

HandyBoard, I/O Expansion Board and Computer Interface

The HandyBoard has both analog and digital inputs. An analog input is a voltage while a digital input is an 8-bit binary number. The digital number is unsigned, assumed to be positive, and between 0-255. The HandyBoard also has an A-D converter. It has the capability of reading a voltage, converting it into a digital number, and outputting this digital number. The HandyBoard’s A-D converter reads a voltage between 0V and 5V and outputs this as a digital number between 0-255. There is a linear relationship between this outputted number and the original voltage. The HandyBoard will output 0 if the voltage is 0, 255 if the voltage is 5 and 128 if the voltage is 2.5. The HandyBoard will use this A-D converter to read 2 sensor outputted voltages: one for the current sensor and the other for the odometer (see section 6.2 Current Sensor Circuit and section 6.3 Odometer Sensor Circuit for interfaces).

Figure 4j displays the HandyBoard along with its I/O expansion, which is hidden under the LCD screen. However, the I/O expansion is not necessary for EEEAHBMS. The I/O expansion allows for more inputs as well as giving the HandyBoard an output to control servos. To the right in the picture above is the computer interface and charger for the HandyBoard. This is used to download programs from the computer to the HandyBoard as well as to keep the HandyBoard’s battery charged. The HandyBoard uses a 9.6 V rechargeable nickel-cadmium battery which will be maintained charged in EEEAHBMS

by the larger sealed lead acid batteries.

The HandyBoard has 4 small H-bridge motor outputs that are meant to drive small motors. One of these motor outputs will be connected to a relay which will activate the automatic shutdown. The other motor output will be used to take the place of the 5k potentiometer. The HandyBoard is capable of putting out between -9V and +9V. As previously mentioned, the HandyBoard only needs to output between 0V and 4V to mimic the potentiometer.

Overall, the HandyBoard will function as the onboard computer in EEEAHBMS. Its purpose it to monitor the system and to collect data during use. It will monitor the speed of the motor, the voltage of the battery, the current of the battery, the voltage of the motor, and various other on-off switches (see section 7 Software Design and Implementation for details) The HandyBoard was recycled from a previous robotics project. While it had no impact on the budget of EEEAHBMS, it originally cost $300.

4.8 Battery Charger

As previously mentioned, sealed lead acid batteries need to be charged in a special way. They require charging at a higher voltage than the normal wet-cell lead acid battery, and are very sensitive to being overcharged. For this reason, an available car battery charger was not appropriate for EEEAHBMS.

The battery charger purchased for the purposes of EEEAHBMS was the 24V EV Warrior Charger. It was located on the same website that supplied the surplus H-Bridge controller. This battery charger was also in surplus, and was purchased for $50. A normal battery charger of the same quality would cost $80.

Figure 4k: EV Warrior

Battery Charger

The EV Warrior Charger has special electronics that make it an effective charger for sealed lead acid batteries. The charger monitors the voltage of the batteries, and when the voltage exceeds a certain threshold voltage, the charger shuts down. Then, when the batteries fall below the threshold voltage, the charger turns itself back on again. This protects the batteries from being overcharged as well as maintaining the batteries at full charge.

The EV Warrior Charger is a 5 amp continuous charger. Continuous means that it will provide 5 amps

of current no matter how close to fully charged the battery is. This is much more effective than a normal

battery charger, where the current decays as the battery becomes more and more

charged. The EV Warrior Charger can

charge both batteries from no charge to almost full charge in a little over 2

hours. Because it is rated at 24 volts,

it is capable of charging both batteries at the same time.

4.9 Bicycle Tire and Tube

In the design portion of EEEAHBMS, it was explained that a mountain bicycle tire would not be compatible with a friction drive system. And, since the prototype bicycle for EEEAHBMS is a mountain bicycle, a new rear tire needed to be purchased.

The only tire with a wide, smooth, thick rubber tread that could be found at the approximate size of the old tire was at www.zapworld.com. The old mountain bicycle tire was a 26 X 1.9, which means 26 inches in diameter and 1.9 inches wide. The replacement smooth tire was a 26 X 1.6. It would suit the purposes of EEEAHBMS perfectly. The bicycle tire cost $12.

When the mountain bicycle tire was first replaced with the smooth tire, it was discovered that the tire tube was not compatible to the new tire. Since the smooth tire wasn’t the exact width as the mountain bicycle tire, the tube would not fit. So, a trip was taken to Cycle Fitness in Monroe and the appropriate tire tube was purchased for $5.25.

4.10 Miscellaneous

While the previous sections enumerate all of the major components that were purchased in preparation for the construction of EEEAHBMS, many small components were also purchased during construction. These include nuts, bolts, aluminum angle stock, mounting boxes, wire, connectors, a t-hinge, screws and washers (see section 5 Construction for their use). In addition, many circuitry components were purchased including a circuit board, a photo resistor, an infrared sensor, operational amplifiers, binary circuit counters, resistors and capacitors (see section 6 Electronics for their use). These materials will be enumerated in the context of EEEHBMS construction.

5. Construction

Once the necessary hardware components were collected, construction of the physical

structure of EEEAHBMS began.

5.1 Saddle-Bag

The largest part and highest priority of the construction process was the “saddle-bag.” This piece could not be purchased and needed to be welded from scratch. However, before it could be welded, it needed to be designed. And this required the use of Computer Aided Design (CAD) Software.

So the design phase for the “saddle-bag” was a three step process:

1. Become familiar with CAD

2. Take measurements and draw the saddle-bag

3. Have the saddle-bag welded

A free copy of the CAD Key ’97 R2 program was available. While it is an outdated program and a limited version of CAD, the picture that needed to be drawn was fairly simple and a current professional version costs over $200. Therefore, CAD Key ’97 R2 was used.

The included guided tutorial seemed to be a logical place to become familiar with CAD Key. This tutorial provided exposure to and instructions on how to use the most basic functions of CAD: object creation, transformation, translation, and linking. However, the tutorial was limited and did not provide satisfactory in-depth instruction. So, a series of self-taught lessons were executed in the form of experimentation. In these lessons, a specific tool was focused on and experimented with until understood. The help function of CAD Key proved to be quite useful in these self-taught lessons. It provided a basic explanation of the purpose of the tool, giving the experimentation some direction. Some of the most difficult aspects of CAD to master were:

1. The 3-D construction view

2. Translating objects

3. Re-sizing objects

CAD Key has 9 different construction views, each with a different orientation of the axes. Five of these construction views are in a 2-D plane, while four are in a 3-D plane. It took much practice to be able to predict what an object in one view would look like in the others. An object could look perfectly acceptable in one view and then be totally distorted in another. And, unless the object looks appropriate in all 9 views, it is not correctly drawn.

Translating objects and resizing objects were difficult for similar reasons. When translating or resizing an object in one axis, it is difficult to predict what would happen with relation to the other objects on a screen. A computer monitor is limited in its ability to display 3-D drawings, and therefore a familiarity with the program is necessary in order to predict the results of a translation or resizing.

Once a comfort level with CAD Key was reached, measurements were taken of the bicycle, motor, and battery in order to formulate accurate dimensions for the saddle-bag. It would be very undesirable for the saddle-bag to be welded and then to discover that the motor does not fit correctly, or that that saddle-bag will not mount correctly on the bicycle. So measurements were taken, checked, and double-checked.

Once all of the measurements were procured, it was possible to begin the drawing. However, a problem was encountered along the way. As accurate as the 3-D CAD drawing could be, it was difficult to understand where certain lines were in relation to one another. So, a color coding system was adopted to differentiate between the pieces of the saddle-bag. However, even with the color coding system, it was still difficult to understand in which plane the holes for the sheave and the mounting of the face of the motor were located. So, two drawings were made. The first was the 3-D picture of the saddle-bag, minus the holes. The second was an “unfolded” version of the saddle-bag, labeled with dimensions and including the holes for the motor.

Figure 5a: The

Saddlebag Folded View

Figure 5b: The Saddlebag Unfolded View:

2” 2” 2” 7”

The large hole in Figure 5b is the hole that the sheave slides through while on the motor shaft. This hole allows the sheave to get to the wheel that the two sides of the saddlebag surround. The smaller holes are the holes meant for mounting the saddlebag to the face of the motor.

With the drawings finalized, it was time to find a welder to build the saddlebag. In early January, a presentation about EEEAHBMS was given to the executives of the Business Education Initiative on behalf of the Trumbull High School Science Department. The Business Education Initiative (BEI) is an organization of business men and women interested in supporting the local education system. This interest extends to donating equipment, time and funding for experiments. The THS Science Department decided to present EEEAHBMS as an example of an independent student project in hopes of encouraging further investment into the science department. The result of the presentation was that multiple business executives became interested in providing assistance along the course of the rest of the project.

John Annick, the CEO of BEI, supplied his phone number if and when aid was needed for the project. When the time came to weld the saddle-bag, it was necessary to call for assistance. John Annick supplied contact information for Art Bradshaw from the Aquarion Water Company in Shelton, CT. A meeting was scheduled, and, after a quick review of the drawings, Mr. Bradshaw said that he would fax the drawings over to Richard Cleri, his welder in Stamford.

By the following Monday, Mr. Cleri had welded the saddlebags out of cold-grey steel. However, the drawings weren’t perfectly accurate. Some of the measurements for the distances of the holes from the sides of the sheet metal were “off”, and, as such, Richard Cleri’s holes weren’t all in the correct locations. However, this was not a serious problem because the large, most important hole for the motor sheave was correct. This was the only hole that could not be drilled without a professional as it is 4 1/2 inches in diameter. The error was in the placement of the mounting holes for the face of the motor. which could be corrected using a hand drill at home. (If Figure 5b is examined closely, the measurements of the piece of metal with the holes in it do not add up to the diameters of the holes and the outside areas. This is where the error was.)

When the saddle bag was examined for accuracy in front of Mr. Cleri, he noted that it flexed a lot under its own weight. This did not bode well for mounting a 24 pound motor and two 9 pound batteries. So, Mr. Cleri quickly uncovered some scrap half inch metal pipe, and cut two 3 inch pieces using a band saw. These two pieces of pipe were to be mounted between the two sides of the saddle-bag in order to greatly increase its strength. Without the two pieces of pipe, the top sheet metal could not prevent the flexing.

Each piece of pipe was attached to the faces of the saddle-bag as in Figure 5c using a 5/8 inch lag bolt with a hexagonal head. A nut was used to secure it in place as well as two lock washers.

Figure 5c: The Welded

Saddlebag

There are two different kinds of lock washers: toothed lock washers and split locked washers. Toothed lock washers are used for the head side of the screw or bolt and prevent the screw from turning. Split lock washers are meant for the nut side of the screw or bolt. They force the nut to be tightened with a lot of torque in order to flatten out the split lock washer. The split lock washer acts like a spring, flattening out as it the nut is tightened. This spring action keeps the nut secure even if it starts to loosen as the split lock washer will just expand to fill in the extra space. Both a toothed lock washer and split lock washer are used on every bolt in EEEAHBMS in order to provide strength.

Once the saddle-bag was strengthened by the addition of the half inch pipe, correctly positioned holes were drilled for the mounting on the motor. After the larger hole was slightly enlarged for the sheave, by using a grinding wheel on a Sears Craftsmen ½ inch drive handheld drill, this aspect of the physical structure was completed.

5.2 T-Hinge and Aluminum

Angle Stock

The next task in the construction portion of EEEAHBMS was to make the channel mountable to the bicycle. There are two mounting points: the seat post and the rear axle of the bicycle.

Figure 5d: Metal

Channel and T-Hinge

The mounting arrangement for the seat post can be seen in Figure 5d. It consists of a T-hinge and piece of 1 inch metal clamp. The T-hinge has three mounting holes, all of which were used in its attachment to the channel. Three ¼ inch holes were drilled in the channel using a small workbench top drill press made in China, model number PTMIN15. Initially, the T-hinge was secured to the channel using a ¾ inch long ¼-20 round head bolt (1/4 inch diameter with 20 threads per inch), nut and lock washers for all three holes. However, later in the construction it was discovered that the rightmost hole in the above picture would block the mounting of the saddle-bag to the channel if a normal bolt and nut were used as planned. Therefore, the screw was changed to a flat head, reversed in its direction (now pointing down) and counter-sunk. Counter-sinking entailed grinding away at the inside of the drilled hole so that the top of the screw would be flush with the channel. With the screw counter-sunk, it would no longer conflict with the mounting of the saddle-bag.

The one inch pipe clamp was chosen because it fit snugly around the seat post of the bicycle. A one inch pipe clamp is meant for pipe with an inner diameter of 1 inch, and an outer diameter of approximately 1 ¼ inches -- an exact match for the seat post. The pipe clamp was secured to the T-hinge using two more ¼-20 bolts, wing nuts, and lock washers. Wing nuts were chosen over hexagonal nuts because they are easier to be undone by hand. And, since these are the nuts that need to be removed in order to mount and un-mount the motor system, it was appropriate to emphasize convenience.

The final addition to the T-hinge was a ¼-20 bolt mounted to the side of the hinge facing the pipe clamp. The head of this screw serves as a shim, ensuring a firm connection between the clamp and hinge and the seat post. This screw head is ground down to give it more of a concave shape in order to make the contact point between it and the screw head smoother.

Figure 5e: Rear

Bicycle Wheel and Aluminum Angle Stock

Figure 5e demonstrates how the support members are connected to the rear axle to support the back of the channel. It is constructed of simple aluminum angle stock. After some experimentation with a pile of screws, it was discovered that the threaded mounting holes in the rear axel accept ½ inch 10-32 screws. However, after experimenting on other bicycles, it was also discovered that European bicycles have a metric standard. Therefore, a different set of screws will be needed to mount to the axle of a European bicycle.

With two long pieces of aluminum angle stock mounted to the rear axle, the channel was mountable. Marks were made for the location of the holes on the channel and the appropriate length of the aluminum angle stock. The measurements were made so that the aluminum angle stock would be angled slightly away from the rider for stability. A purely vertical mounting arrangement would not be as strong.

To add flexibility to the mounting arrangement, extra holes were drilled into the channel and into the support members. By using a different set of holes, the height of the channel with respect to the wheel, and the angle at which the aluminum angle stock is mounted can be varied. The aluminum angle stock is connected to the channel by the standard ¾ inch ¼-20 bolts. Standard wing nuts and two lock washers are also used.

Since all bicycles have different sized tires, the distance

from the channel to the rear axle will not be constant. Therefore, in the final design of EEEAHBMS,

the aluminum angle stock support will have to have a variable length. This can be accomplished by two pieces of

aluminum angle stock that slide over one another.

5.3 Motor and Batteries

The next step in the construction process was to secure the motor, batteries and control box to the saddle bag. With the large hole enlarged for the sheave and the mounting holes for the face of the motor corrected, the mounting of the motor required only sliding the motor into place and bolting it to the side saddle. However, since the motor is the most important and heaviest of the components of EEEAHBMS, it was decided that redundancy in the mounting of the motor is appropriate. Therefore, while normally either only the motor face mounting holes or the motor base mounting holes are used, both are used for EEEAHBMS. Two holes were marked and drilled with the drill press for the mounting of the base of the motor and the standard ¼-20 screws, hexagonal nuts, and lock washers are used.

The mounting of the face of the motor wasn’t as simple as assumed. With the holes drilled, the only step left was to screw into the threaded holes. However, the 3/8 inch bolts purchased wouldn’t fit. It was through this experience that it was discovered that there are two types of threads on large bolts: coarse and regular threads. And, the threaded holes on the face of the motor are made for coarse threaded bolts. Therefore, special nuts had to be purchased as well, with standard lock washers being used.

Figure 5f: Motor

mounted on Saddlebag

The mounting of the batteries was not straightforward, since the batteries have no mounting holes. The first thought was to strap the batteries to the saddlebag. However, it was quickly realized that this would be highly unstable and the batteries would most likely slide around. Therefore, a more effective design was necessary.

The battery mounting design involves a tray which would slide in and out of the saddlebag. The batteries would be clamped to the tray, and the tray would be bolted in place to the saddlebag. The tray’s mounting point would be adjustable, giving it freedom to be mounted farther in or farther out, until it effectively balanced the weight of the motor. Fabricating this metal tray would involve the same steps of fabrication as for the saddlebag. However, with the deadline for EEEAHBMS quickly approaching, this complicated battery tray was added to the future improvements list, and a simpler approach was devised.

The problem was that the batteries did not fit snuggly into the saddlebag tray. They had much room to slide around in. So, pink Styrofoam was cut and used as a spacer, making the fit for the batteries tighter. Then, a metal bracket was attached to the back of the saddlebag, securing the motors into place.

Figure 5g: Batteries

Mounted on Saddlebag

The metal bracket was secured with the standard ¼-20 bolts,

nuts, and lock washers

5.4 Mounting of Saddlebag

Once the batteries and motor were mounted to the saddlebag, it was possible to mount the saddlebag to the channel. The channel was temporarily mounted to the bicycle and then the saddlebag was positioned such that the sheave would be placing an acceptable amount of pressure of the wheel of the bicycle. Two holes were marked and drilled using the drill press. Finally, the saddlebag was secured with the standard ¼-20 bolts, hexagonal nuts, and lock washers.

There is much flexibility in this mounting system. The point at which the channel attaches to the seat post is one point of adjustment. By mounting the channel higher and lower, the sheave puts a varying amount of pressure to the bicycle wheel.